Structure and Mechanical Behavior of Bulk Nanocrystalline Materials

The reduction of grain size to the nanometer range (2-100 nm) has led to many interesting materials properties, including those involving mechanical behavior. In the case of metals, the Hall-Petch equation, which relates the yield stress to the inverse square root of the grain size, predicts great increases in strength...

In-situ TEM tensile testing of DC magnetron sputtered and pulsed laser deposited Ni thin films

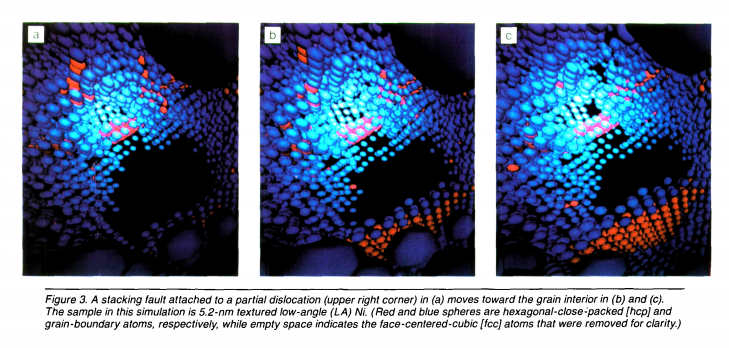

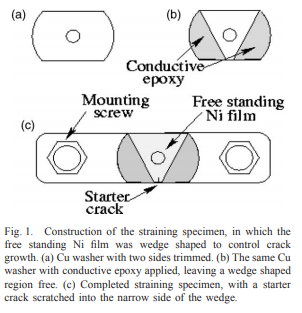

Two nanocrystalline Ni thin films, one prepared via DC Magnetron Sputtering and the other prepared via Pulsed Laser Deposition, were strained in-situ in the Transmission Electron Microscope. Although the grain sizes were similar, the two films behaved quite differently in tension. The sputtered material was found to be...

Mechanical behaviour and oxidation resistance of structural silicides

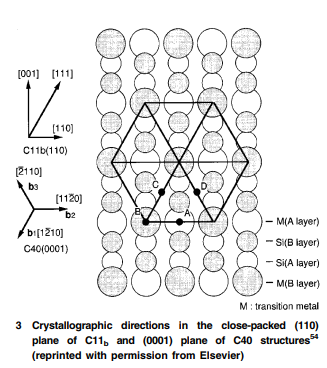

The need for high performance materials in aerospace, automotive and industrial components operating at temperatures in the range of 11001500C has led to a surge in the research and development of the refractory metal silicide based intermetallics, multiphase alloys and composites. The silicides of Mo, W, Ti, Nb and Cr...

Creep and fatigue properties of high temperature silicides and their composites

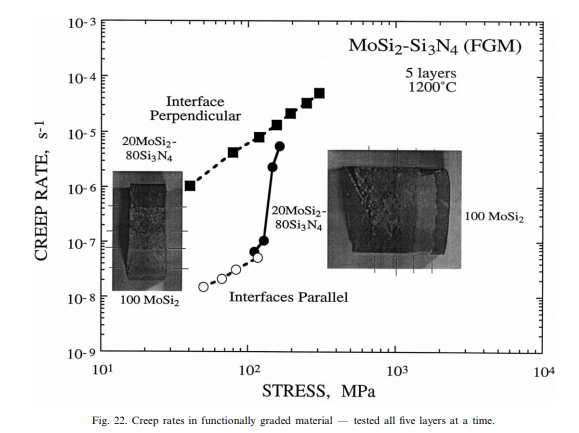

A review of creep and fatigue behavior of high temperature silicides and their composites is presented along with new results pertaining to titanium silicides and functionally graded materials . The emphasis was placed on the molybdenum disilicides and their composites in comparison to other silicides and high temperat...

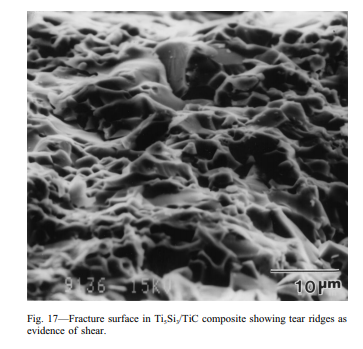

Microstructure and mechanical behavior of reaction hot-pressed titanium silicide and titanium silicid

Titanium silicide (Ti 5 Si 3 ) and its composites show promise for applications at temperatures higher than 1000 C. Dense Ti 5 Si 3 was processed by reaction hot pressing of a TiH 2 /Si powder mixture, which involved decomposition of TiH 2 into Ti and H 2 at around 800 C, a chemical reaction between Ti and liquid Si at...